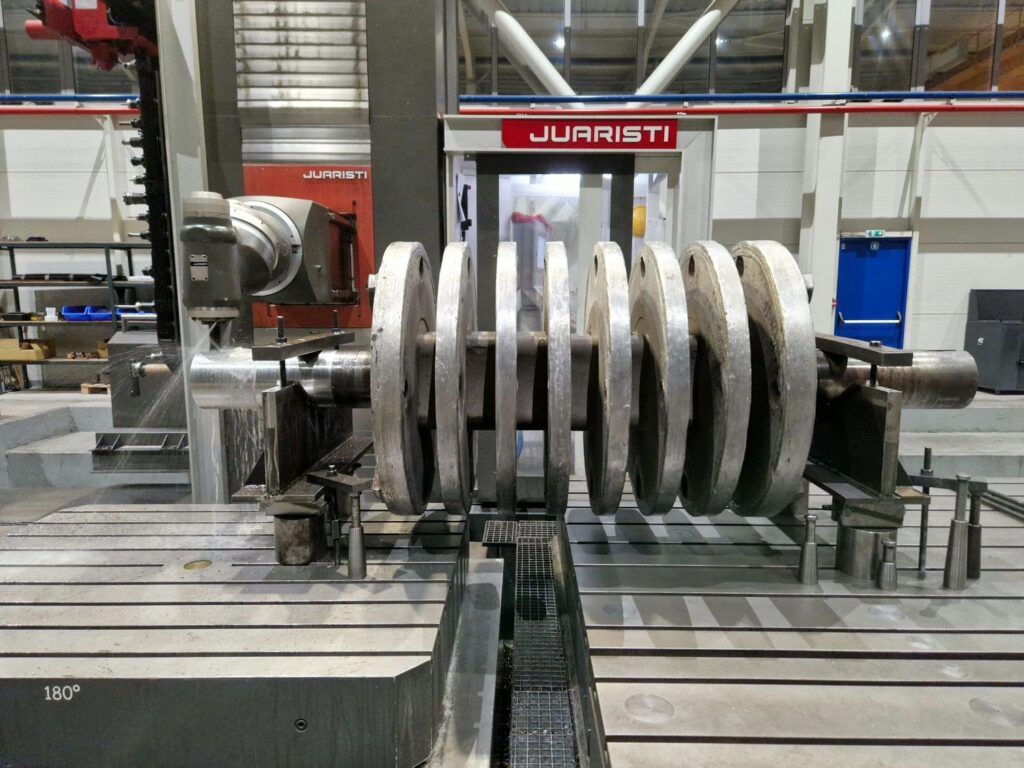

The crasher rotor of ANOXAL SA, suffered sustained damaged on one end caused by poor lubrication which led to bearing stuck. Both rotor ends were dismantled, inspected (measurements and NDT) and checked for runout.

The maximum runout of 13mm was found on the right shaft rotor end.

Machining of bend right end was carried out on our CNC heavy duty turning lathe, to prepare the surface for regeneration in our Laser Cladding cell.

Chemical analysis and hardness inspection was performed in order to identify the based metal and choose the right alloy powder for build-up

After regeneration of the surface by Laser Cladding and stress relieve, the rotor end was machined to its nominal dimensions by CNC turning and CNC milling.

Last the coupling was modified to fit on customers working position and the rotor assembled with new bearings.