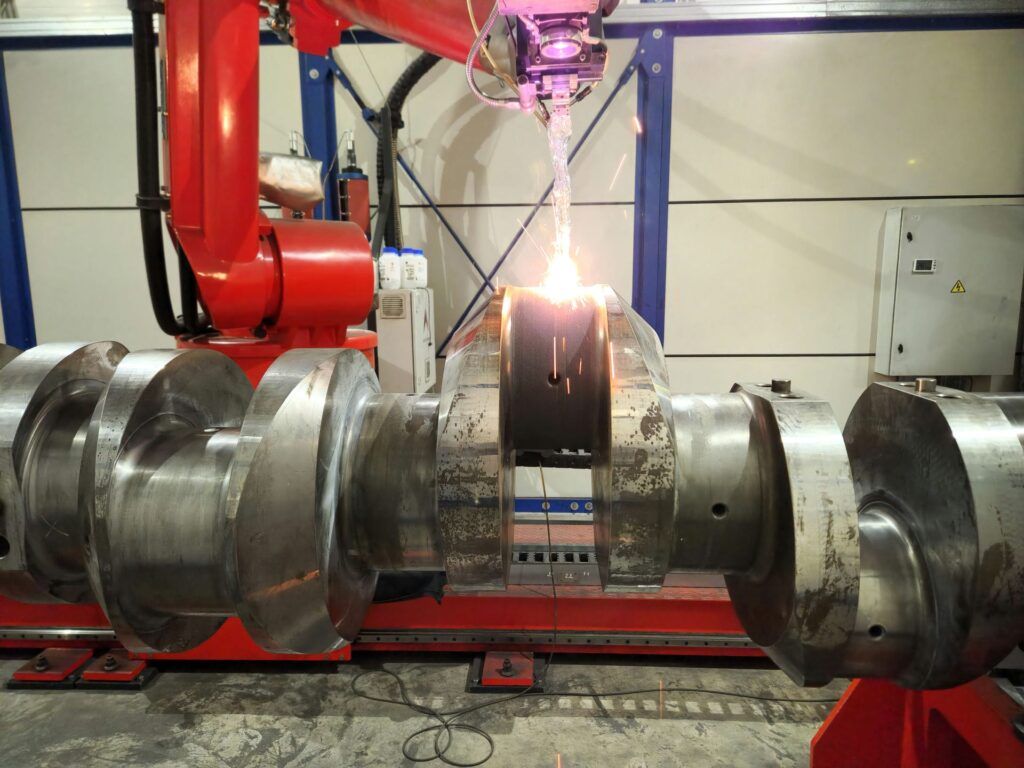

Marine crankshaft repairs is a key service for TKPitsirikos S.A. Having great experience and know-how in the repair of critical components, in 2013 and after extensive research and cooperation with European specialized laser cladding institutes and testing series, our company certified the process of repairing 4stroke marine diesel crankshaft repairs with the method of Laser Cladding in cooperation with classification society Bureau Veritas for thickness up to 10 mm radially. Since then we have repaired many crankshafts for shipping companies and shore based engines all over the world with absolute success.

Through continued research and investment in both mechanical equipment and technology, we have become specialized in Marine crankshaft repairs and can safely and reliably restore any four-stroke crankshaft to its original condition.