Our company has great experience in overhauling-repairing various types of gearboxes and fabrication of gears.

Recently we completed the overhaul of main engine shaft generator gearbox type Mekanord PT1500-2, which suffered from a massive crack on the lower casing and had to be repaired.

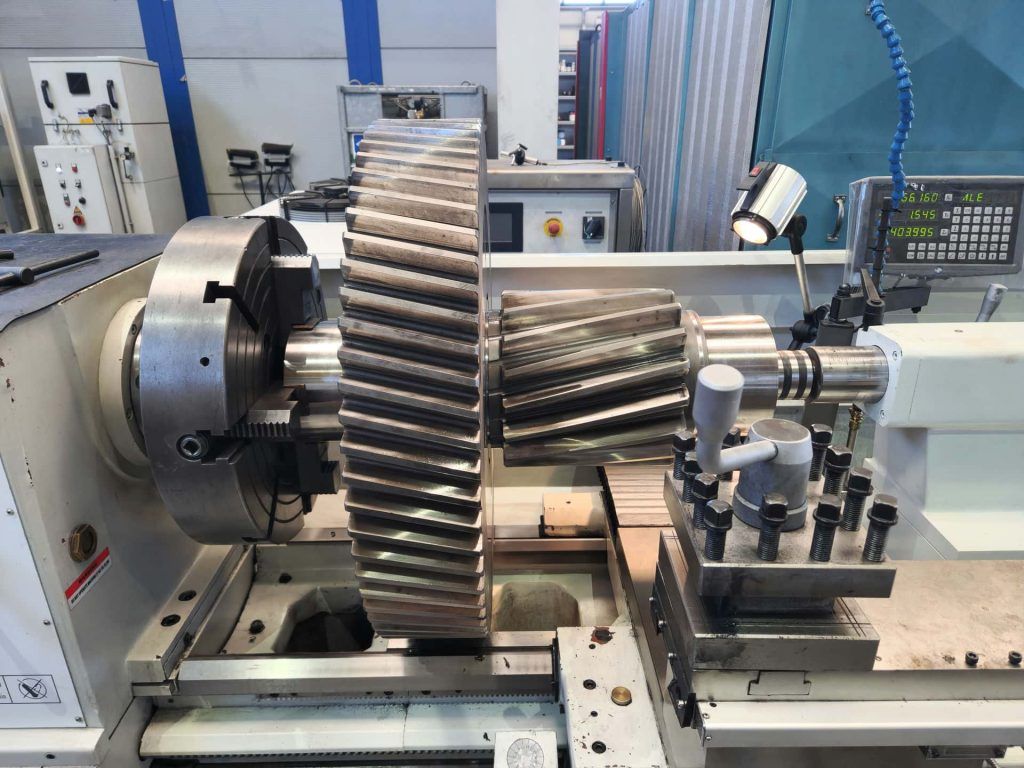

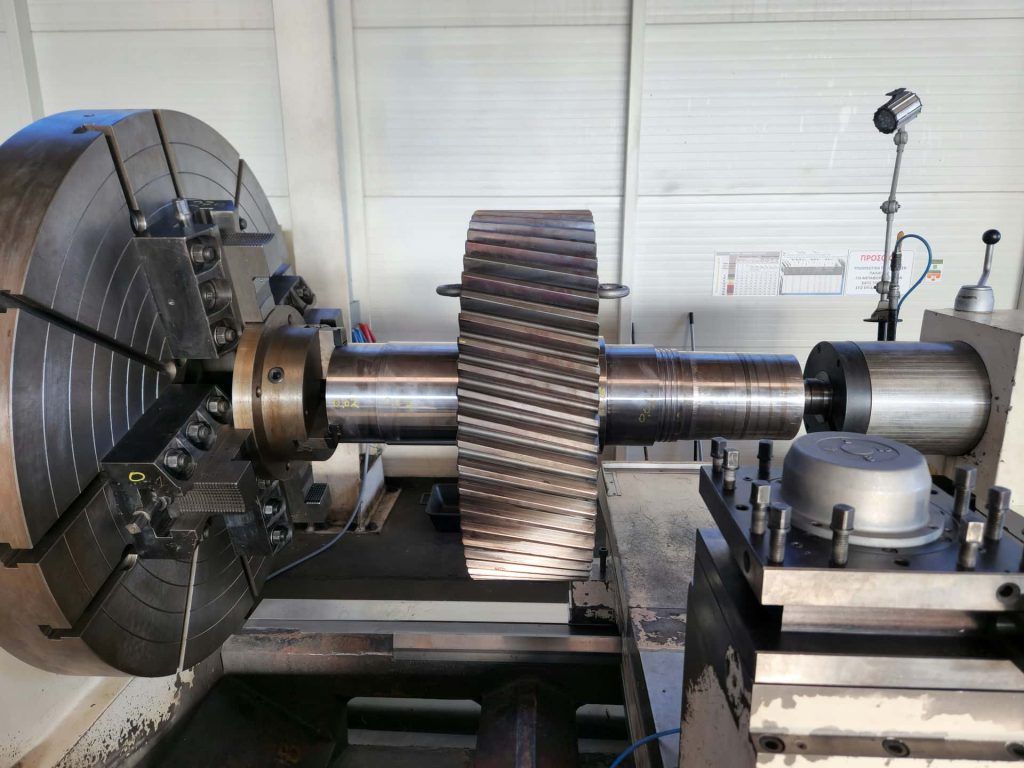

The gearbox was dismantled, cleaned thoroughly and inspected. All gears were removed and checked for run out and gear teeth were NDT inspected. The lower and upper casing were too inspected and measured. Measurements revealed that the gearbox was distorted and machining to restore parallelism between the upper and lower faces as well as the centerlines of the working gears, was necessary.

Before proceeding to machining, the crack was isolated and repaired following a special welding procedure suitable for cast iron.

The overhaul of main engine shaft generator gearbox continued with the gearbox repair on our CNC boring and milling machine where upper and lower casing faces were machined as well as all bearing pocket diameters and faces. Full geometrical restoration was carried out.

Finally, overhaul of main engine shaft generator gearbox had completed, it was assembled with new ball bearings and delivered to customer in full working condition.