During major overhaul and repair of a main sheet plate leveling machine for our customer ERGOTEM, the gearwheels were found with severe damages and had to be replaced.

All gearwheels originally made by casting, went through chemical analysis, hardness measurements and 3-D modeling.

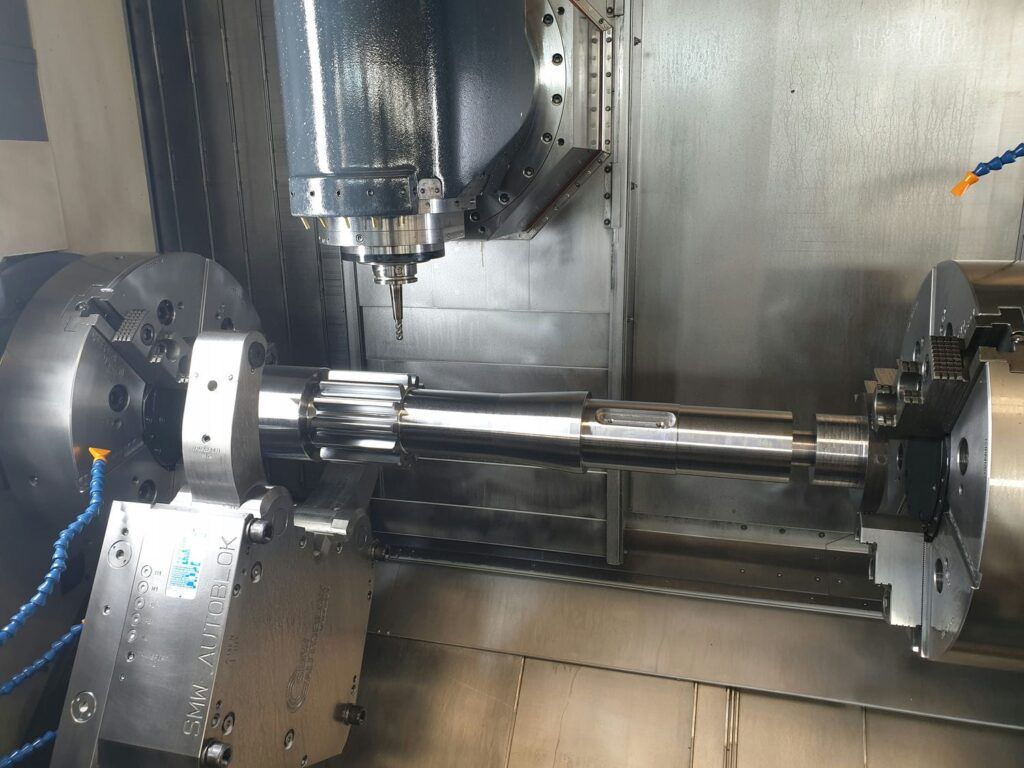

The new gearwheels and pinion were manufactured out of forged steel plates and shaft respectively, on our full 5-axes CNC machines which can cut any gear teeth geometry by milling with high accuracy.

The lead time for producing the gearwheels and the pinion was reduced significantly since through this technique the necessary time for casting pattern and casting was as well as the time for the required hobbing tool was avoided.