Being incessantly loyal into providing top quality services to our customers, we are driven by a never ending passion to invest and bring the most innovative technological advancements in Greece.

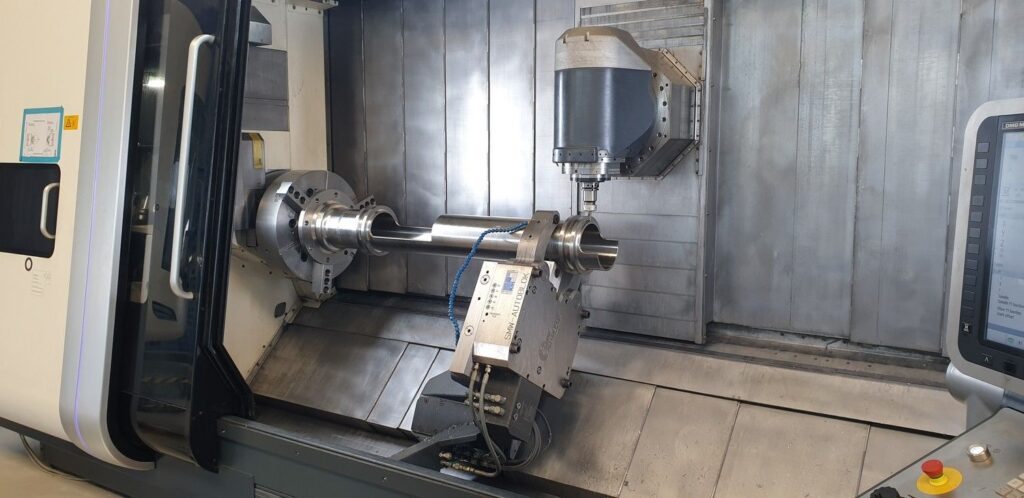

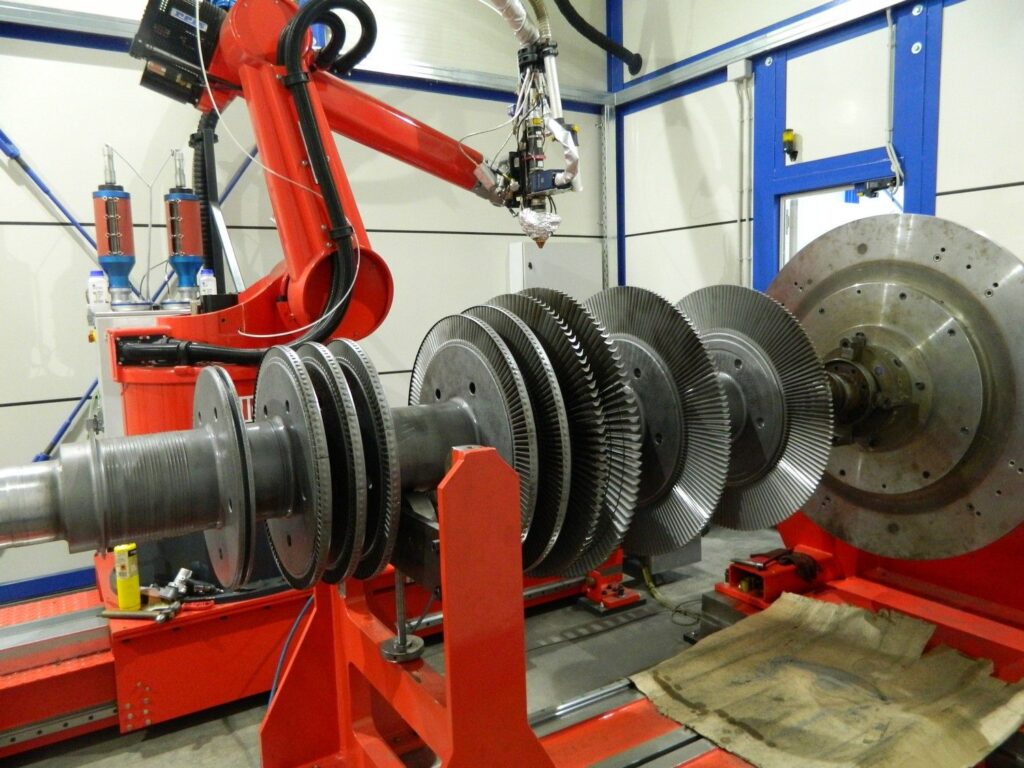

We operate in a state of the art facility, located in the Industrial and Entrepreneurial Area of Keratea, which is fully equipped with the most potent CNC machines and robotic laser cladding and welding Systems.

Our repairing & manufacturing solutions have gain all these years veneration from clients doing business in the Power Generation Industry (Fossil & Renewables), the Marine Industry, the Defense Industry, Oil & Gas Industry, the Metals Processing Industry and the Railway Industry.

Our vision

Our aspiration is to play protagonist role in the area of Europe, as one of the most competitive “one stop shop” mechanical workshops.

Our mission

To maintain our identity as trustworthy and rigorous partners that treats your work-needs with passion and integrity.

Our Facilities

Our modern workshop is situated in a strategic location, very close to the major ports of Athens-Greece (Piraeus and Lavrio Ports) and just few minutes away from Athens international Airport and the railway station.

Our

Equipment

Our infrastructure consists of modern CNC multi axis machines as well as conventional, modern Robotic Laser Cladding and Welding Cells, in-house Metallurgical and Quality Control equipment, sophisticated surface scanning-Reverse Engineering equipment and CAD/CAM systems.

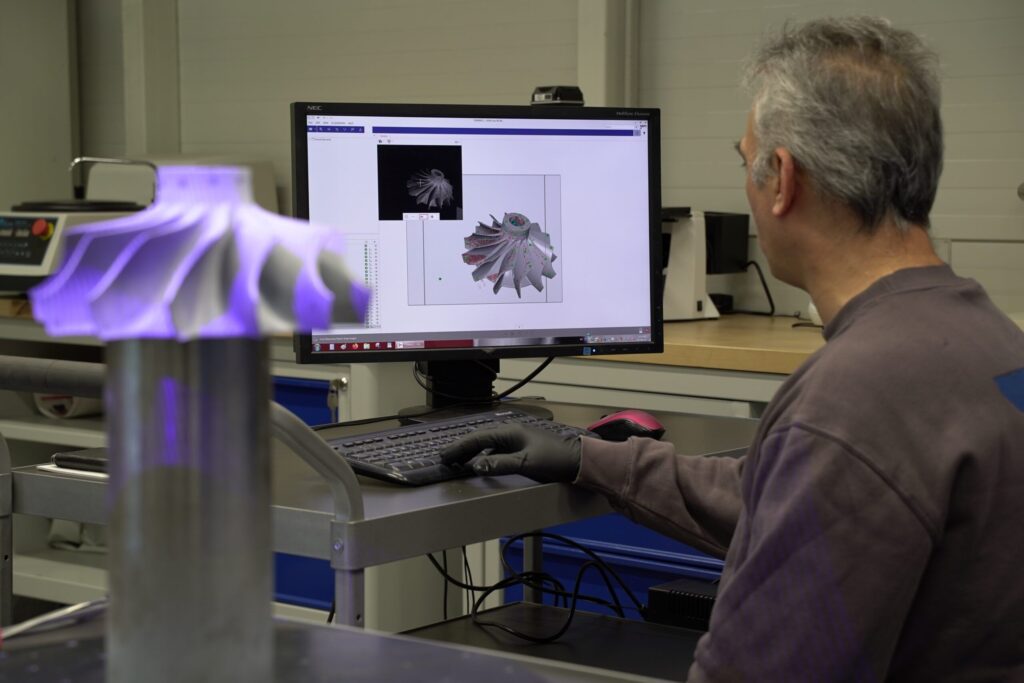

Reverse

Engineering

We are one of the few mechanical workshops in Europe which employs a high amount of specialized staff of mechanical engineers, metallurgists and designers able to bring what is needed into the table.

Up to date we have manage to produce OEM quality components for various industries, through Reverse Engineering, helping our customers to save time and money.

Every project that comes to our hands receives the utmost attention and takes its place into a fined tuned procedure, where everything is performed according to the highest quality and safety standards imposed by ISO recommendations.

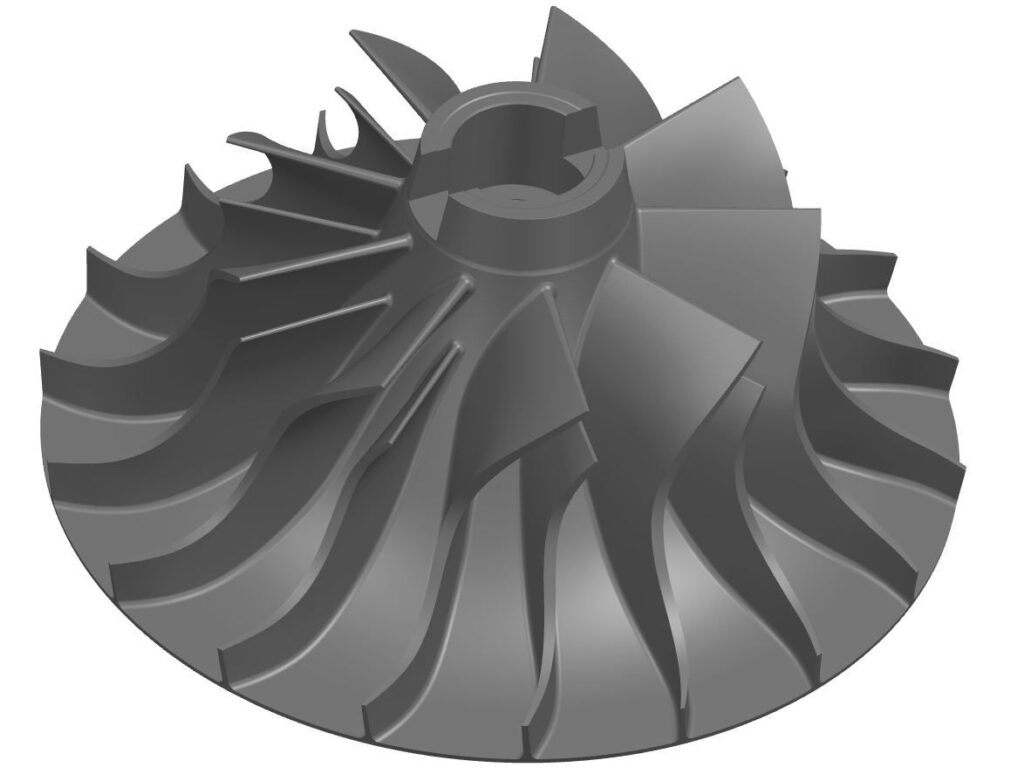

The core stages of Reverse Engineering include the following processes, through which we manufacture high quality components at short delivery times and competitive pricing:

- High accuracy optical non-contact surface scanning or touching probe scanning

- 3D modeling and surface optimization

- Derivation of engineering manufacturing drawings

- Chemical analysis by mass spectrography equipment

- Metallographic inspection

- Hardness, Coating thickness, Surface roughness measurements

Quality Control

& Material Analysis Laboratory

We are committed in short deliveries and competitive prices but never at the expense of quality.

Every operation taking place during the process of overhauling, repairing, and manufacturing is being strictly monitored from our Quality department which is consisted of accredited metallurgists.

Qualified inspectors in non-destructive and destructive tests are inspecting all incoming equipment and components for defects prior, during processing and right before dispatching to the customer.

Detailed report containing the findings, of first hand inspections, is being compiled upon receipt of a component, in order to keep aware the customer regarding the condition of the project.

In case of detection of malfunctions our technical department informs the client about viable and cost effective repair or manufacturing options.

All these years of doing businesses, we keep unchanged the principle of maintaining long-lasting business relationships with our suppliers.

We buy top quality raw materials and consumables, accompanied each time by the appropriate certificates, but we also perform our own tests to verify their properness.

During processing, our engineers intervene at critical stages, with appropriate controls to ensure that the quality is maintained throughout all stages. Prior to delivery, the same engineers carry out the final quality control.

Quality tests mainly include:

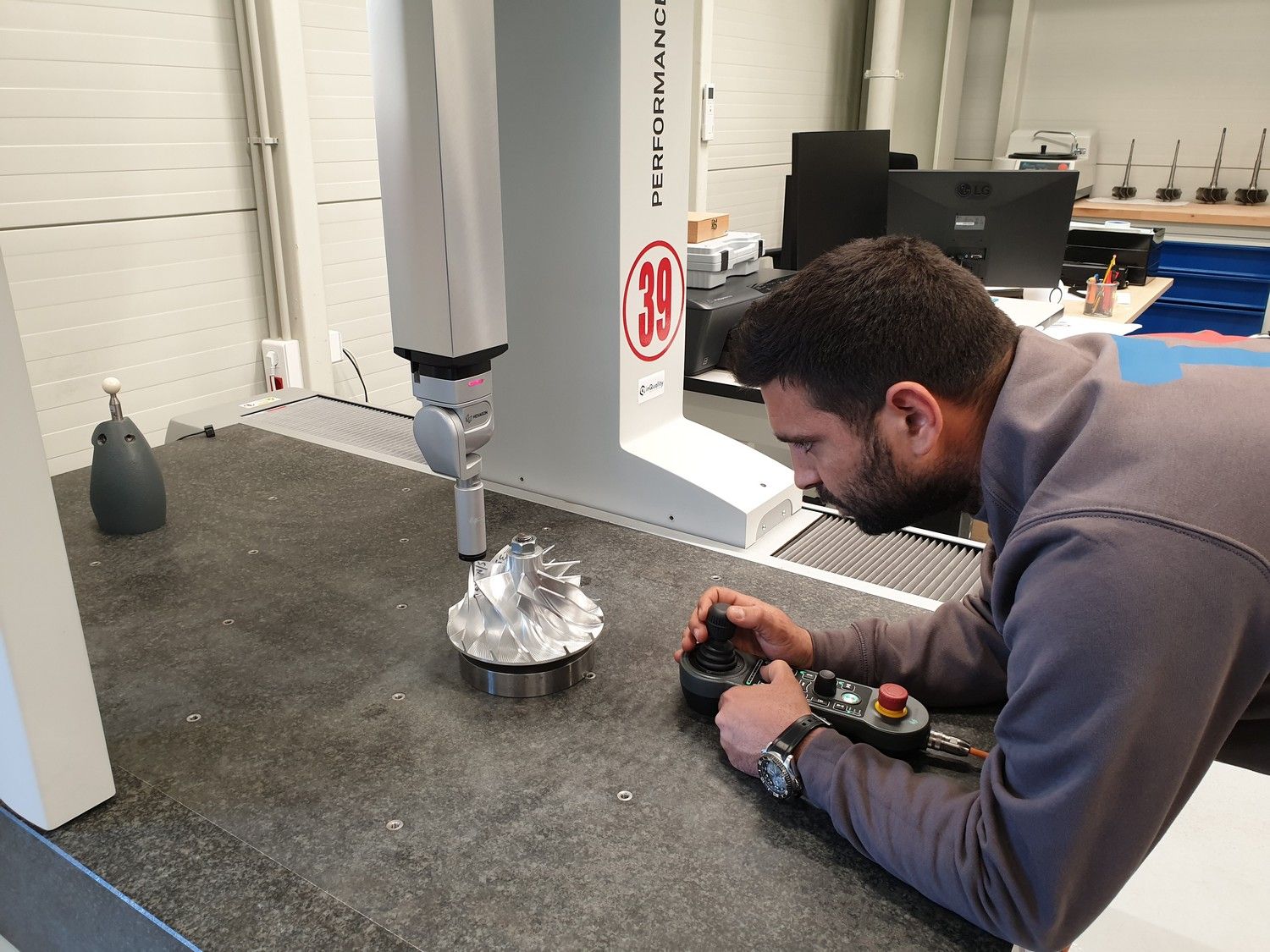

- High accuracy dimensional measurements by CMM

- Optical 3D scanning

- Non-destructive tests with penetrating liquids or magnetic particles

- Ultrasonic tests

- Hardness and roughness measurements

- Coating thickness measurements

- Crack depth measurements

- Endoscopic inspections

- Metallographic inspections

Our Quality Control and Metallurgical Laboratory is accredited by ISO 17025.