We are one of the few mechanical workshops in Europe which employs a high amount of specialized staff of mechanical engineers, metallurgists and designers able to bring what is needed into the table.

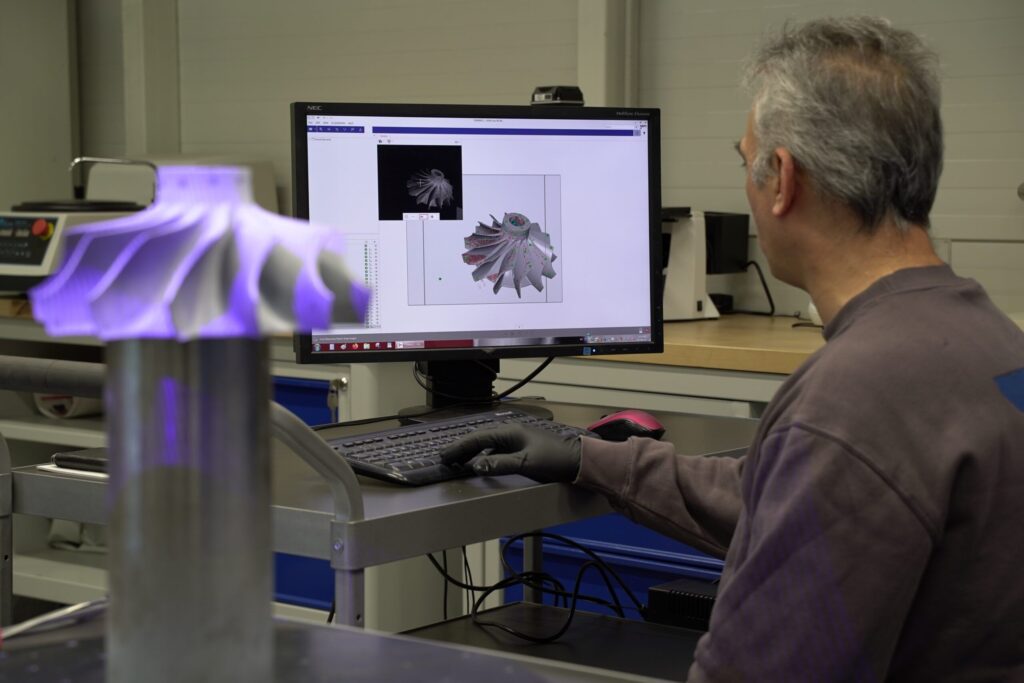

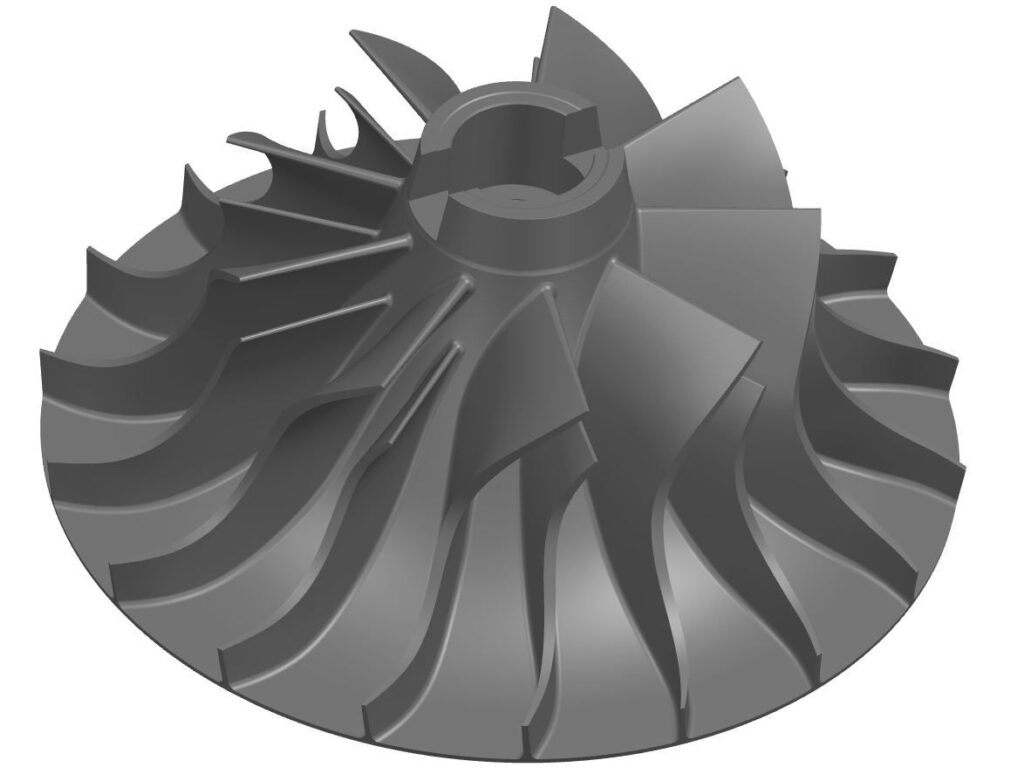

Up to date we have manage to produce OEM quality components for various industries, through Reverse Engineering, helping our customers to save time and money.

Every project that comes to our hands receives the utmost attention and takes its place into a fined tuned procedure, where everything is performed according to the highest quality and safety standards imposed by ISO recommendations.