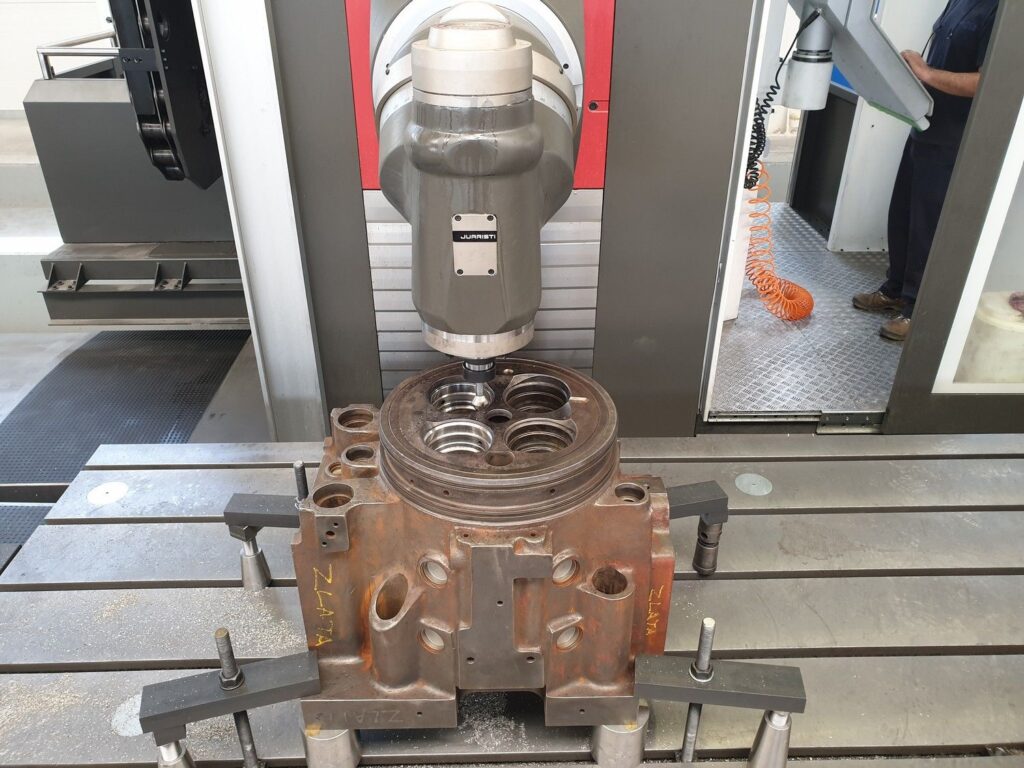

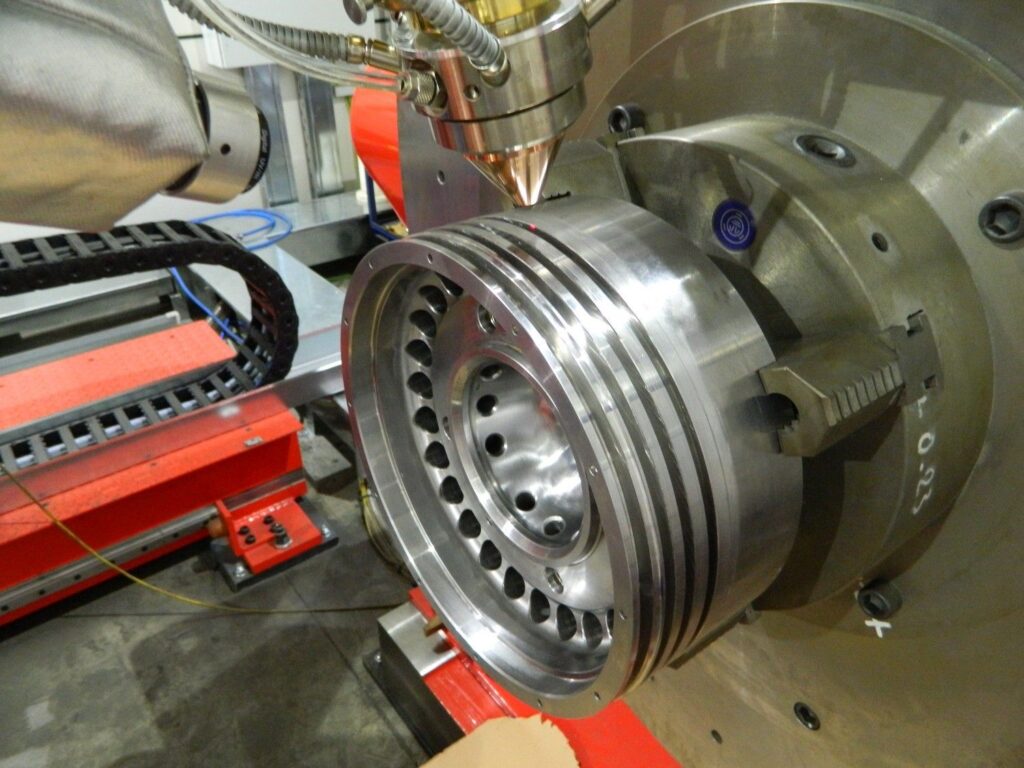

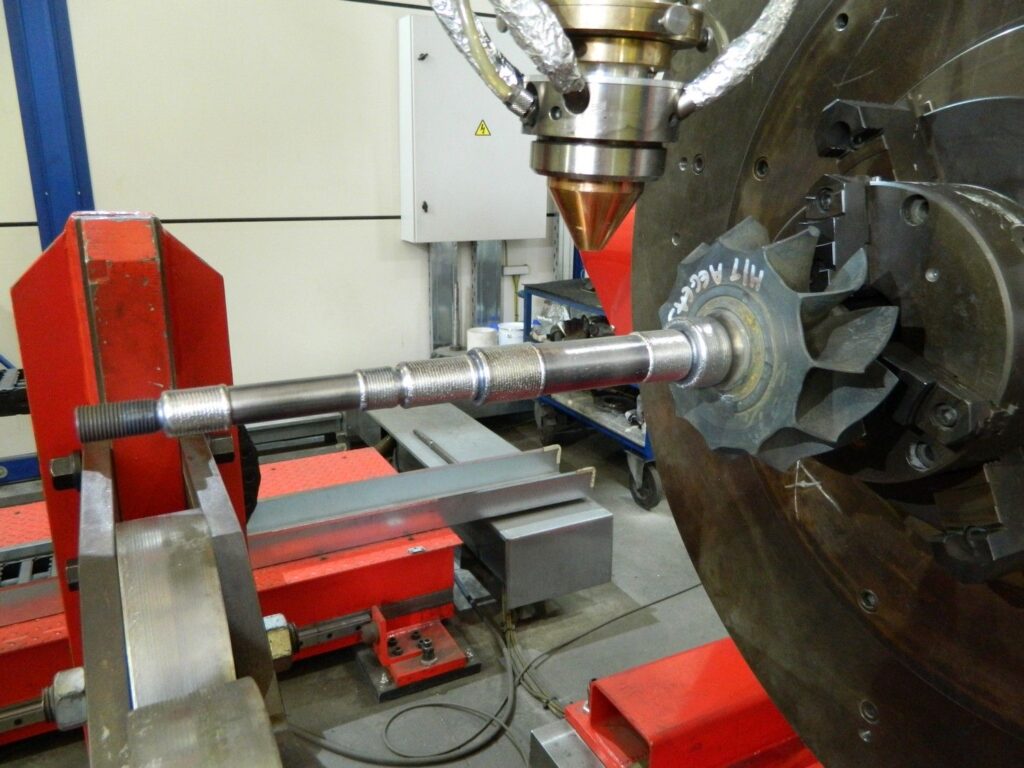

Having extensive experience and deep know-how in marine diesel engine services, we repair spare parts and overhaul equipment of high importance for all types of auxiliary and propulsion 4stroke diesel engines.

During overhauling we rigorously follow the procedures imposed by makers. All components are thoroughly cleaned and inspected and worn out parts are replaced with new ones where applicable or restored by machining (connecting rod ovality restoration, cylinder head mating surfaces skimming, liner honing, etc).

Too often, customers come across situations where standard maker’s procedures are simply not enough due to severe damage and core components need to be replaced. This is where we stand and offer alternative solutions that reduce overhauling costs drastically.