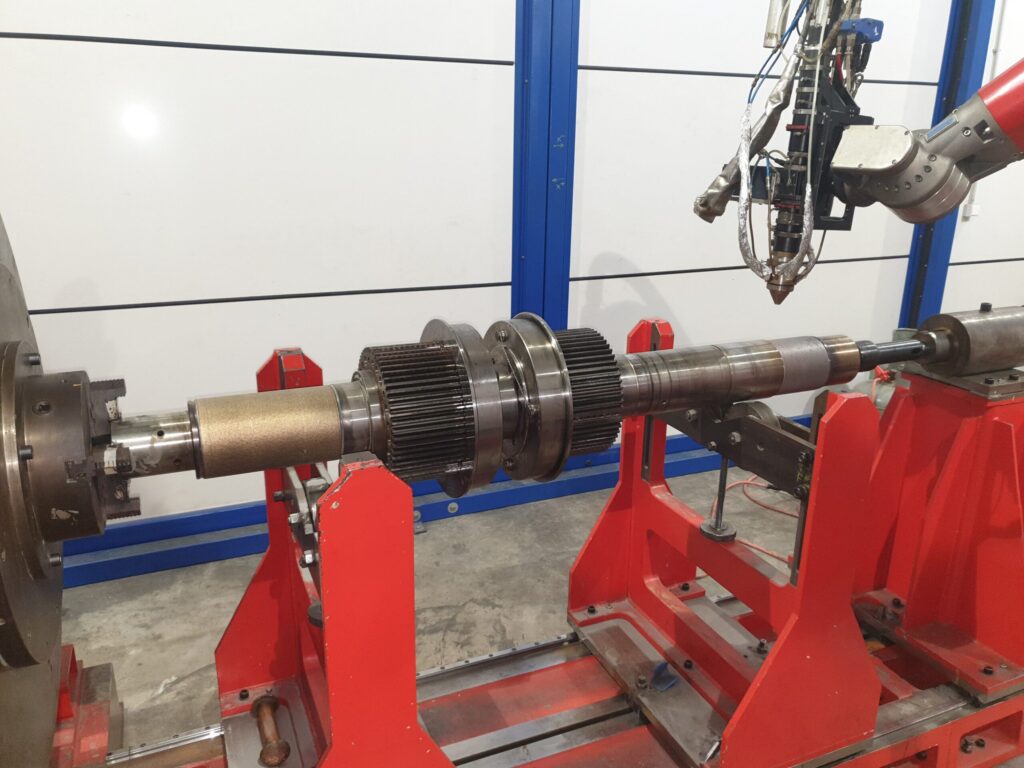

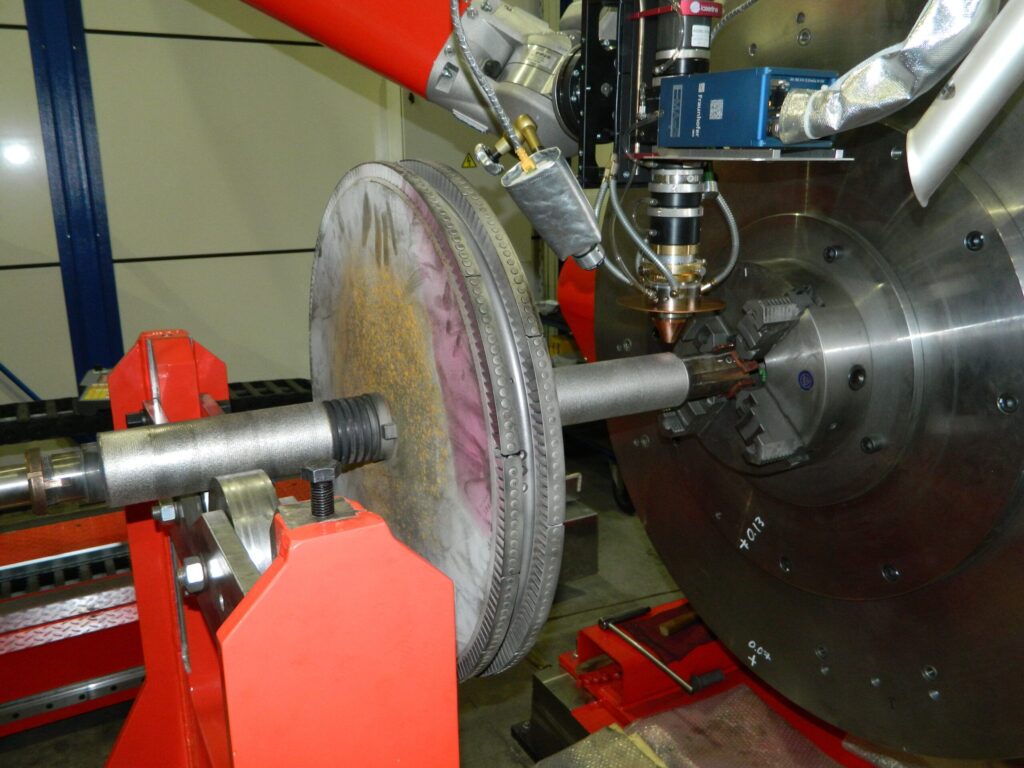

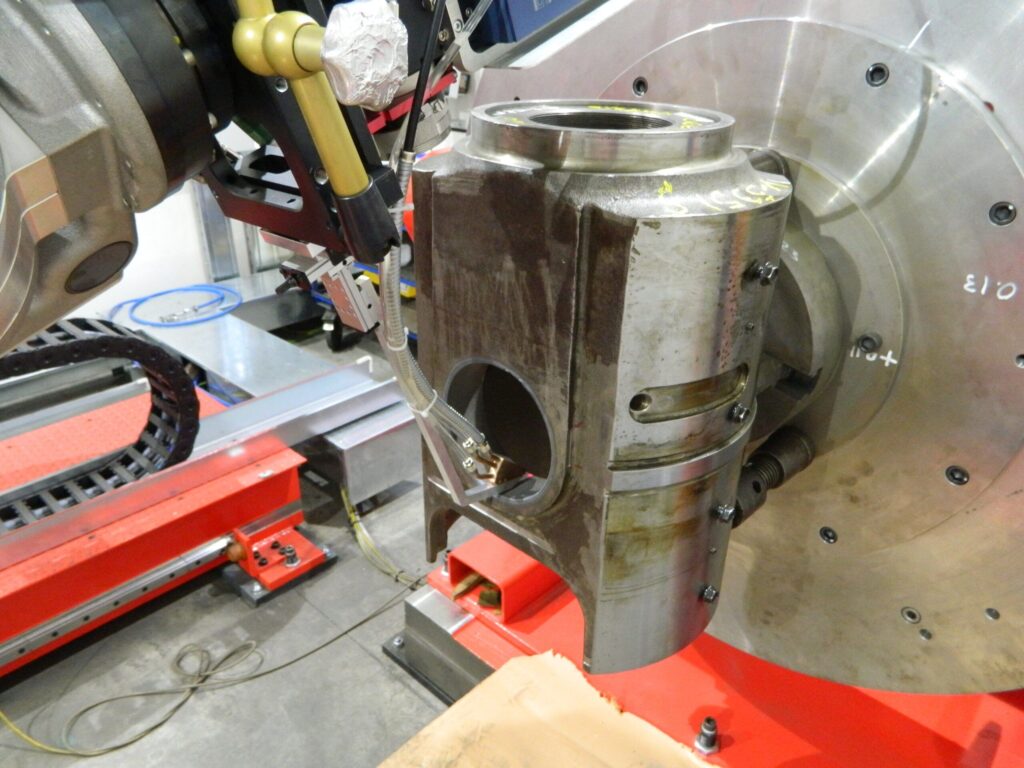

Laser Cladding Services.

Since 2011, when we first installed and started utilizing our sophisticated laser cladding cell, we have gone through remarkable breakthroughs and innovations, which have helped our customers to reduce tremendously maintenance costs.

Unlike the existing surface build-up methods, most of which starting to become obsolete in time, laser cladding with its extreme preciseness is here to completely rebirth critical value components and offer the competitive advantage that companies are searching for.